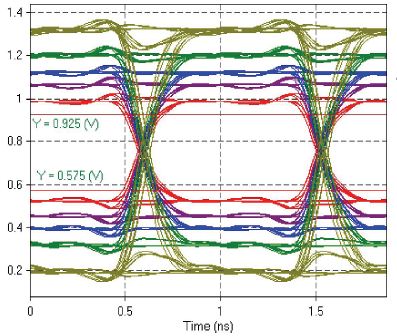

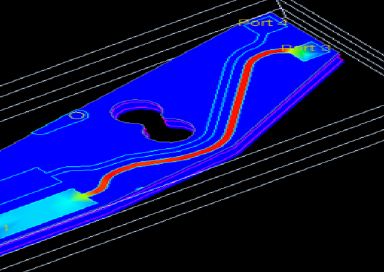

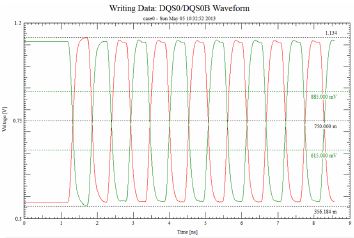

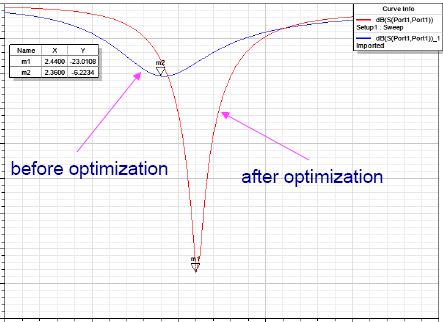

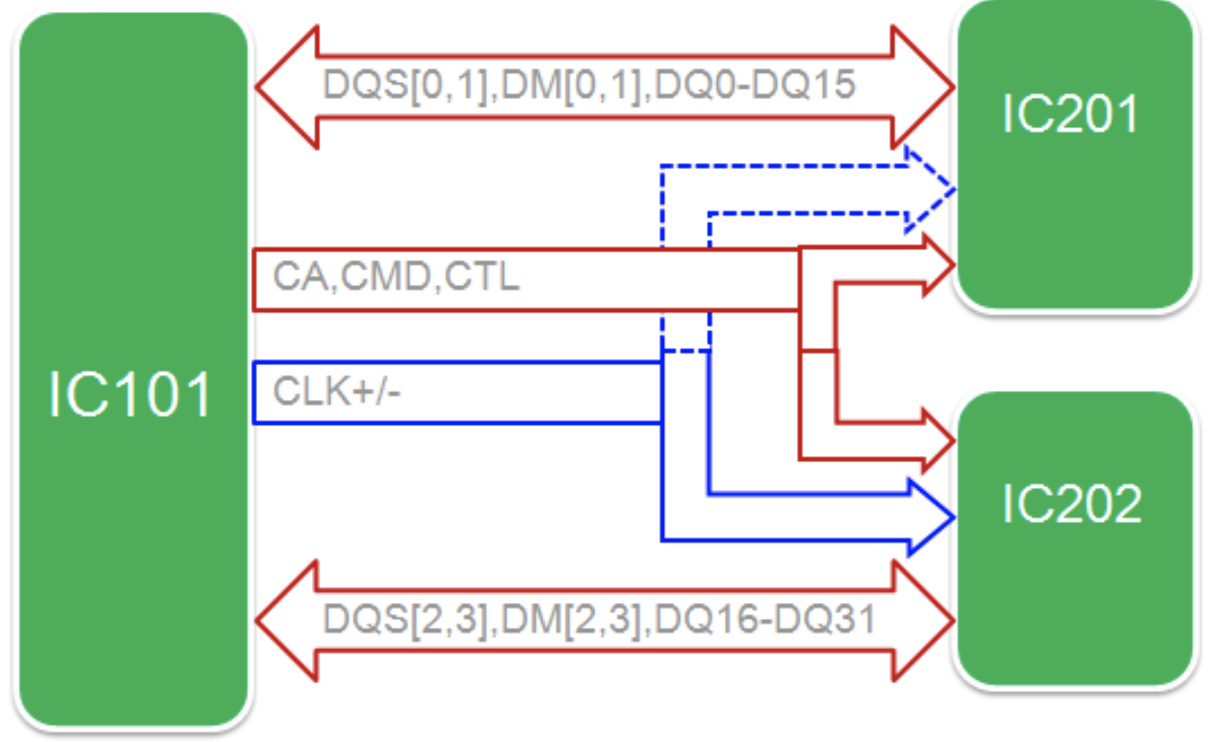

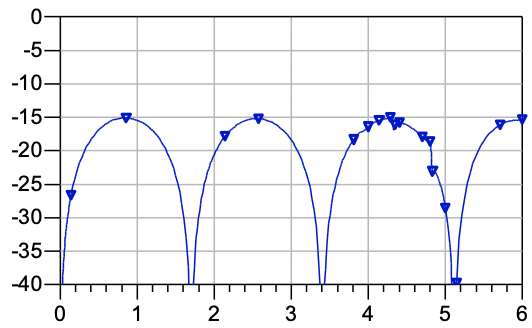

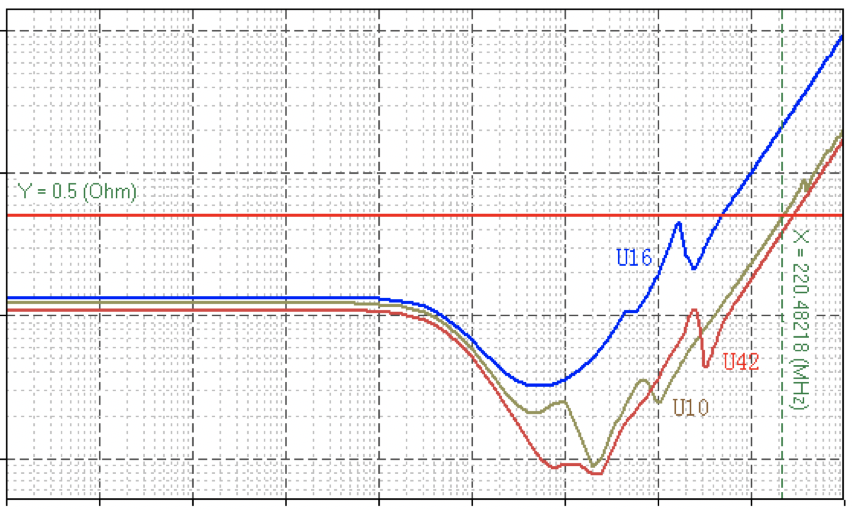

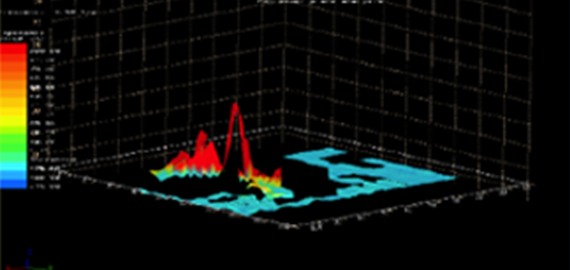

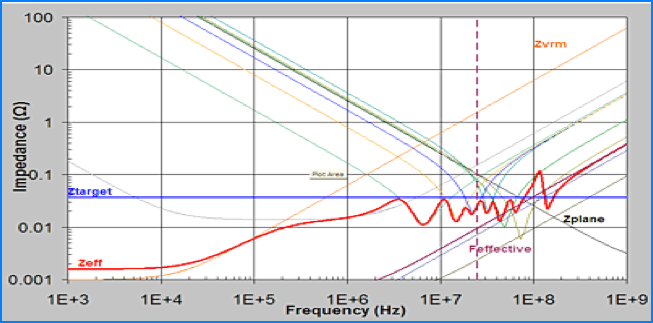

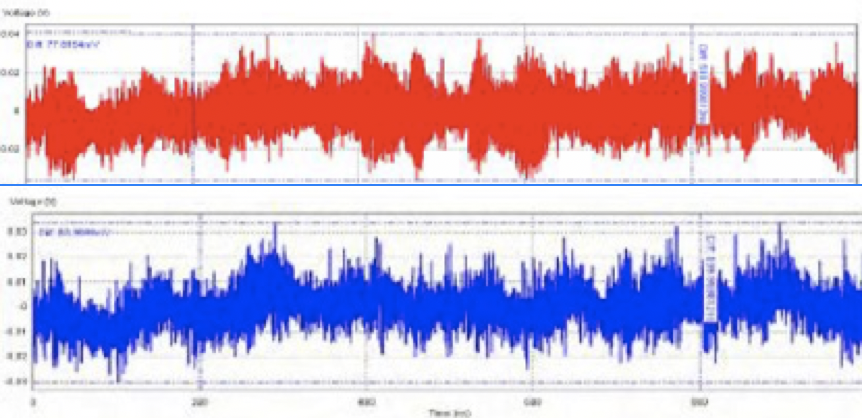

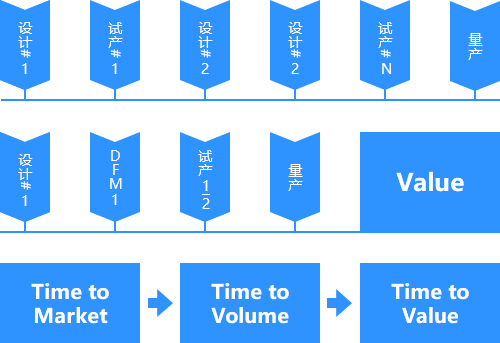

SI, PI, EMC, DFM, comprehensive simulation and design.

Give full consideration to simulation anlysis for design.

Throughout tech support from Japanese senior engineers.

Extensive hands-on experiences and successful projects.

Able to perform signal simulation analysis over Giga Hz and above.